Introduction

In the UK’s renewable energy sector, MCS compliance is a critical quality assurance benchmark, especially for professionals engaged in solar PV, heat pumps, energy storage, and EV charger systems. Though MCS (Microgeneration Certification Scheme) is technically voluntary, it is deeply embedded in the incentive, subsidy, and credibility frameworks that drive project viability. Installers, engineers, and project managers who understand how to achieve and maintain MCS compliance not only reduce risk, but also strengthen client trust, streamline project workflows, and unlock access to government-backed programs such as the Smart Export Guarantee (SEG) or heat pump incentives.

In this guide, we’ll explore the context of MCS, explain the core requirements by technology, highlight common challenges, present practical workflows, and show how platforms like Reonic can support compliance steps in your project pipeline. By the end, you'll have a robust toolkit to approach MCS compliance with confidence.

Background: What Is MCS and Why It Matters

What is MCS?

The Microgeneration Certification Scheme (MCS) is a UK-based independent quality assurance scheme for small-scale renewable energy technologies and their installation. MCS certifies both products (e.g. solar panels, heat pump units) and installers (and their installations) against defined technical and procedural standards. It is UKAS-accredited, meaning the scheme aligns with formal accreditation norms.

Why MCS matters in practice

- Access to incentives and export tariffs: Many government and utility schemes require that eligible installations or installers are MCS-certified. For example, only installations by MCS-certified installers qualify under the SEG scheme for solar exports.

- Market credibility & risk mitigation: Clients increasingly demand proof of quality and reliability; having MCS compliance can differentiate your business.

- Standards alignment: MCS ensures consistent, auditable, and repeatable installation practices and product performance, reducing defects and disputes.

- Ongoing compliance obligations: MCS compliance is not “set and forget.” Installers must maintain processes, audits, and technical quality over time.

Legal vs de facto requirement

Technically, MCS certification is not legally mandatory to install renewable systems. However, because many key incentives and customer expectations depend on MCS, failing to comply can severely restrict your business potential.

In sum: for many professionals, MCS compliance is effectively essential for large-scale uptake, quality assurance, and competitive market positioning in the UK renewable sector.

Core Requirements for MCS Compliance by Technology

Each technology (solar PV, heat pumps, battery storage, EV charging) has its own technical and procedural compliance requirements, beyond the baseline installer scheme. Understanding these is key to full compliance.

General Installer Scheme Requirements (MCS 001 family)

Before we dig technology-specifics, every installer must satisfy the base scheme criteria:

- Company-level compliance to MCS 001-1 / 001-2, which define requirements for contractor status and the certification process.

- Quality Management System (QMS): you must implement and document processes covering design, commissioning, health & safety, complaints, etc.

- Competency / personnel requirements (MCS 025): you need a Nominated Technical Person (NTP) for each technology, and evidence they hold approved trainings.

- Consumer protection and codes: membership in an approved Consumer Code (such as RECC or HIES) is required.

- Certification Body audits and site inspections: you will be assessed by an accredited certification body, including sample site visits.

- Continual reassessment: You will have to maintain compliance, conduct audits, and respond to non-conformities over time.

- Scope limits: MCS typically applies to installations up to certain sizes (e.g., up to 50 kW electrical).

Solar PV & Battery Storage

Key requirements specific to PV (and PV + battery) include:

- Product certification: all modules, inverters, storage units must be MCS-certified under the relevant product standards (e.g. MCS 005, MCS 010).

- Design & performance estimates: your proposals must include predicted yield (e.g. via software), shading analysis, module layout drawings, datasheets, and assumptions.

- Commissioning & documentation: you must fully commission, record test metrics, provide client handover packs, and register the installation in the MCS Installation Database (MID) to issue the certificate.

- Electrical compliance and safety: compliance with IET (Institute of Engineering and Technology) Code of Practice for Grid-Connected PV, wiring auditable trails, earthing, isolation, etc.

- Export meter / monitoring: to qualify for SEG, you must incorporate correct metering or export measurement and monitoring.

Heat Pumps (Air Source, Ground Source, etc.)

For heat pumps, MCS compliance follows similar patterns with its own technical standard:

- Product compliance: heat pump units must be certified under the relevant MCS product standard (e.g. MCS 006).

- Sizing & heat loss calculations: you need accurate heat load calculations, design of pipe sizing, refrigerant lines, controls, etc.

- Noise / planning constraints: depending on planning/permitted development rules, noise calculations (e.g. MCS 020a) may be needed.

- Commissioning & performance testing: you must log COP (Coefficient of Performance), flow temperatures, and commissioning report details.

- Handover & documentation: you must provide full user guides, maintenance schedules, and issue the MCS certificate.

EV Chargers & Storage Integration

While EV chargers per se may not always require MCS certification, when designed as part of integrated systems (e.g. PV + battery + charger), compliance is important in upstream design and electrical safety:

- Ensure wiring, protection coordination, and grid interface comply with electrical safety and local regulations.

- For battery systems integrated into PV or heat pump systems, the battery must be certified (e.g. MCS product standard where applicable).

- Data and monitoring integration must support performance logging and fault tracing.

Common Challenges & Pitfalls

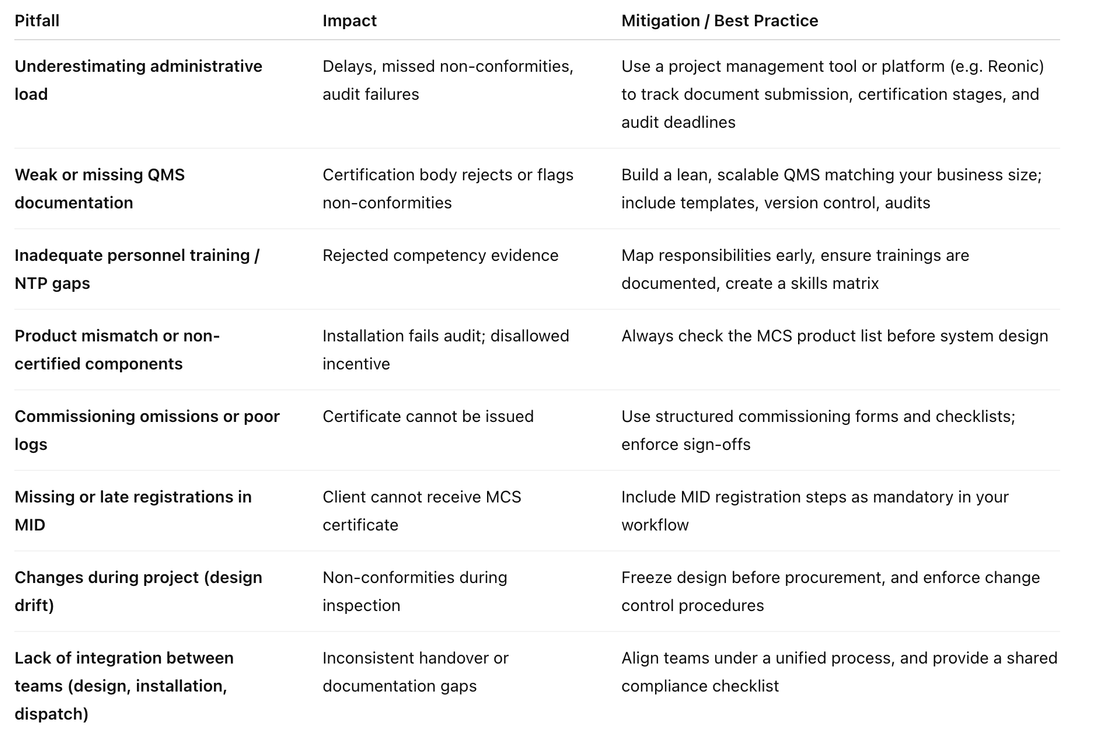

Understanding the requirements is one thing; successfully executing MCS compliance in projects can be tricky. Below are frequent challenges and suggested mitigations.

By detecting these risks early and incorporating them into your project planning, you can reduce surprises during certification audits.

A Compliance Workflow: From Quotation to Certification

Here’s a sample step-by-step workflow for ensuring MCS compliance in a project:

- Pre-qualification / Quoting stage

- Confirm that the client expects MCS compliance (if incentives or SEG are involved).

- Verify that specified components are MCS-certified.

- Prepare initial yield or heat load estimates using standardized tools.

- Internal design & review

- Create full design package: layouts, wiring diagrams, calculations.

- Internal compliance review against checklists (QMS, product list, design requirements).

- Freeze design before procurement.

- Procurement & inspection

- Order components, inspect on arrival, verify datasheets and certificates.

- Tag components for tracking in compliance records.

- Installation & commissioning

- Use preapproved procedures under QMS.

- Record commissioning tests (voltages, currents, COPs, etc.).

- Test safety protections, isolation, monitoring systems.

- Client handover & reporting

- Provide handover packs: user manuals, warranties, compliance documents.

- Collect signed acceptance by client where required.

- Prepare and review final certification package internally.

- MID registration & certificate issuance

- Register the installation in the MID (MCS Installation Database).

- Issue the MCS certificate to the client.

- Audit & quality reviews

- Facilitate certification body site inspections.

- Address any non-conformities in time.

- Log learnings and update QMS accordingly.

- Ongoing maintenance & compliance

- Monitor system performance and fault reports.

- Schedule periodic internal audits or reviews.

- Renew or maintain certification with the body annually or as required.

A structured tool or platform can embed these steps, trigger reminders, and prevent compliance steps from being missed.

How Reonic Can Help in MCS Compliance

While this article is not promotional, it’s worth highlighting how a project management and design platform (such as Reonic) fits naturally into the MCS compliance journey.

- Task tracking & compliance pipelines: You can create a built-in compliance pipeline (pre-design, procurement check, commissioning, MID registration) to ensure no step is skipped.

- Document and version control: Store datasheets, certificates, commissioning reports, QMS templates, and associate them with projects.

- Team collaboration and audit logs: Track who signed off which compliance task and when — useful for internal audits and certification body reviews.

- Component library with certification metadata: Tag your material catalog with MCS-certified status so unapproved components aren’t accidentally used.

- Templates and checklists: Embed compliance checklists in your workflow to ensure site teams follow the same procedure each time.

- Notification & alerts: Get reminders for upcoming audits, certificate renewals, or missing documents.

In complex projects, these features can cut administrative friction and reduce the risk of missing a compliance step under pressure.

Case Study: Solar + Battery Project with MCS Compliance

Scenario

An installer company in the UK bids for a domestic solar + battery + EV charger system, in which the homeowner expects to benefit from the Smart Export Guarantee (SEG). The system is sized at 8 kWp PV + 12 kWh battery + AC charger.

Key compliance points handled:

- Component selection: Every module, inverter and battery unit was verified against the MCS-certified product list.

- Design package: The design included yield estimates (per shading model), inverter layout, AC coupling diagrams, export meter wiring, and datasheets.

- Commissioning protocol: During commissioning, DC voltage, current, insulation resistance, battery charge/discharge efficiency, and protective relay tests were logged.

- MID registration: After commissioning, the project was entered into the MID, and the certificate was generated.

- Certification body inspection: A sample of the site was inspected — the auditors checked the documentation, wiring consistency, safety, and documentation alignment with design.

- Outcome: The certificate was approved without non-conformities; the homeowner qualified for SEG payments, and the installer used the project as a reference for future bids.

This example illustrates how detailed attention to each compliance phase ensures smooth certification.

Conclusion

MCS compliance may initially appear as a bureaucracy hurdle, but for UK renewable energy professionals, it is one of the pillars of project quality, client trust, and eligibility for financial incentives. By understanding the scheme’s requirements, anticipating common challenges, and embedding structured workflows and tooling (for instance via Reonic or similar platforms), you can convert compliance from a risk into a business advantage.

If you’d like, I can help you shape a project-level checklist or Reonic compliance pipeline template specific to your technology mix. Let me know.

FAQ — MCS Compliance

Q1: Is MCS compliance legally mandatory in the UK?

No, MCS compliance is not legally required for installation. However, many incentive programs and export tariffs require installations to be carried out under MCS-compliant standards.

Q2: What are the steps to become an MCS-certified installer?

You need to:

(1) Familiarize yourself with MCS 001 and the technical standard(s);

(2) appoint a Nominated Technical Person (NTP) and demonstrate competency (via MCS 025)

(3) implement a suitable QMS;

(4) join an approved Consumer Code;

(5) apply to a Certification Body for audit and site assessment.

Q3: Can I use non-MCS certified components and still be compliant?

A: No. To comply under MCS, all major system components (modules, inverters, etc.) must be MCS-certified under the respective product standards. Using non-certified components jeopardizes the certification.

Q4: What is the MCS Installation Database (MID) and why is it important?

The MID is where certified installations are registered. Only after registration in the MID can the installer issue the official MCS certificate to the client. Failing to register in MID means no valid certificate.

Q5: How often do I need to maintain or renew my MCS compliance?

Compliance is maintained through ongoing audits, internal reviews, and updating processes over time. Certification bodies typically require periodic reassessments (often annually or per their schedule).

Q6: Does MCS compliance apply to battery storage or EV chargers?

Battery systems often fall under MCS product and installation standards when integrated with PV or heat systems, so compliance is relevant. EV chargers alone may not always require MCS certification, but when part of a larger system, compliance and electrical safety need to be managed carefully.

Q7: What are common reasons for non-conformities during site audits?

Some frequent causes include missing documentation or commissioning logs, discrepancies between design and installation, use of non-certified components, insufficient QMS records, or failure to register in the MID.

Q8: How can a software platform help with MCS compliance?

A platform can embed compliance checklists, track document workflows, enforce step signoffs, manage versioning and audit histories, and trigger notifications — reducing human error and administrative overhead in achieving MCS compliance.